The making of beautiful jewels might seem like magic if you’re ignorant of the steps in the manufacturing process. If you’re a jewelry enthusiast, it’s only natural that you want to learn more about the process of manufacturing jewels. If you want to know the steps in jewelry manufacturing, you’re at the right place. This post will take you through all the steps, from designing the model to the quality check.

Here you go.

Essential Steps in the Jewelry manufacturing process

Designing a 3D Jewelry Model

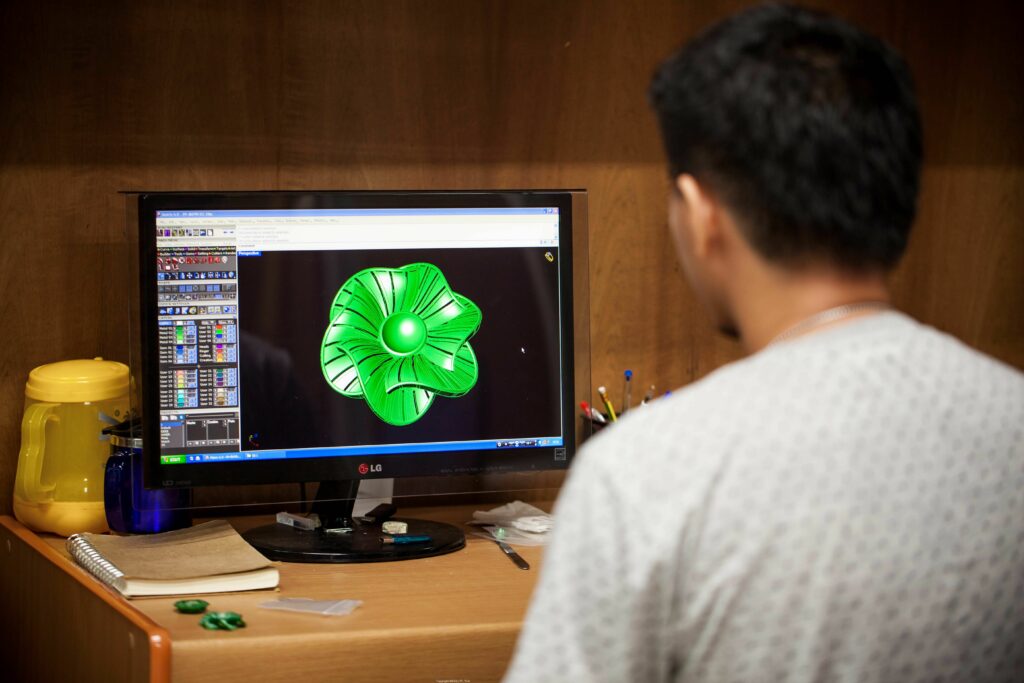

After developing the initial sketch, jewelry manufacturers start to make a digital model of the jewelry. Using CAD (Computer-Aided Design) software, the 3D designer will render the jewelry in 3D. Depending on the project’s complexity and the artist’s workload, this process can take anywhere from a day to a week. The goal here is to create a preproduction render of your jewelry made for functionality and not aesthetics. If the jewelry doesn’t look as pretty as you envisaged, the final piece might end up looking different. That said, you can always request a more detailed render.

Wax Carving

After the studio completes the 3D render of the jewel, the next step in the jewelry manufacturing process is creating a detailed wax model by a computer-aided wax-making machine. The computer file of the 3D model is transferred to a milling machine to cut out a wax model. You can also use a 3D printer to make an exact copy of jewelry. The wax version of your jewelry prototype is the closest thing you’ll see to your final jewelry. If it doesn’t look appealing to you, here is your chance to ask for a remake.

After a computer-aided 3D print of the wax prototype of the jewelry, the prototype goes to the molding department. This department uses crude equipment like knives to manually carve all the details in the wax to make it a piece of perfect jewelry. The hand carving process creates a more organic design. It showcases the vibrant curves and softer sensibility of the jewelry piece.

Basic Jewelry Assembly

After your jewelry passes through the design and casting stage, the final fabrication can take anywhere between 3 days to weeks. At this point, the jeweler refines the main structure of your ring, necklace, or other jewelry. The jeweler files down the casting skin to reveal the metal underneath. Although casting transforms the jewelry into fine metal, the jeweler needs to make aesthetic adjustments to confirm that the piece can support gemstones functionally. After completing the mount, the jewelry is ready for stone setting. However, any enameling or additional work takes place before the stone setting.

Pre-Polish

Jewelry polishing is a multiple-stage process where the metal is polished with soft rotary tools made from bristles, felt, or muslin. It applies in descending stages, from coarse to fine. The wheels are charged with several polishing compounds to achieve the desired luster. While buffing and polishing are commonly used interchangeably in the jewelry manufacturing industry, they’re very different terms. Buffing is the abrasive process that involves removing a part of the jeweled surface to keep it smoother.

Tripoli is the most commonly used compound for buffing. You can remove minor scratches left from sanding by buffing, but they will not bright polish. Jewelry pieces typically require buffing before setting the gemstone. Once you set the stone, the area below the gem portion will be impossible to polish, affecting the shine. The final high luster is achieved by polishing which will comes at the last stage of jewelry manufacturing. After buffing, jewelry manufacturers polish the stones to achieve the high luster that makes the jewels enticing.

Polishing uses resistant compounds like rouge and doesn’t remove the surface of the jewelry. There are many varieties of rouge used in jewelry manufacturing, distinguished by color. Rouge polishes jewelry with almost no cutting action; it burnishes the metal and moves the surface layer around to smoothen the scratches left from buffing. This process reveals the physical properties of the jewels, making it a crucial jewelry manufacturing process.

Stone setting

Stone setting is the next step of the custom jewelry manufacturing process. In the case of a typical wedding ring or engagement ring where gemstones are involved in the design, they must be set in place. Setting gemstones in a ring or other jewelry requires various techniques and settings. Settings are otherwise the methods of integrating a precious stone to metal. To create more intricate or complex designs, jewelers can use multiple settings during the stone setting process.

Polishing

The goal of polishing is to add some shine to the entire piece of jewelry. Polishing comes after the stone setting process, and it can either be done by hand or by a machine. When hand-polishing jewelry, the craftsman uses different tools like solid buff, soft buff, hair buff, coin buff, single line ball buff, green rouse for shine, platinum polishing rouse, black luster for removing casting/filling layers, red rose, and white sheen to remove roughness.

Rhodium Plating

Rhodium is a sparkling white-colored precious metal. Plating a piece of jewelry with rhodium gives it a characteristic white reflective appearance and provides better resistance to scratches and tarnish. It is commonly used on yellow gold to create visually appealing patterns or designs. Using Rhodium plating on white gold adds to its whiteness since white gold isn’t very white in its pure form. Quality checks The final step of the custom jewelry manufacturing process is quality control. Jewelry manufacturing

This step sounds simple, but it requires three separate and equally important steps that no reputable custom jewelry manufacturer ever skips. First, a jeweler will measure the piece to ensure it meets the designer’s requirements. Then they will perform a thorough visual inspection. If the jewelry passes the visual inspection, the quality checker then subjects it to mechanical inspection typically performed on the clasps, chains, and bands of the jewelry piece to verify its strength, quality, and stability. Jewelry manufacturing

Conclusion

Jewelry can be beautiful, but a great many steps go into their production. Who would’ve ever imagined that a simple wedding ring goes through eight complex manufacturing processes? If you’re curious what those eight steps are, feel free to read this article. Here, you’ll learn how jewelry manufacturers make jewelry, from the concept design to the quality control. Jewelry manufacturing